The sliver cans manufactured for the spinning industry are used…

Why are Caster Wheels important?

Caster wheels are important as they ensure smoother movement of the Cans in the mill floor. Be it automated machine movement, or manual pushing of Cans from one area to another – the quality of caster wheels, smooth movement and durability happens to be few of its very important aspects.

Challenges Faced By Spinning Mills

Spinning Mill floors are bumpy and rough. Major problem of cotton dust exists on the floor. Cotton hairs or fluff that fly around and most of the time end up getting attached to the caster wheels. This fluff accumulation hinders smooth movement of the cans.

The problem aggravates when loaded sliver cans are required to be moved from one place to another. Mill workers, in these cases, really have to push hard to get the move. But, such a scenario is not at all desired. It hampers the overall process. Also, it affects the wheels too.

Sliver Cans when loaded should get into a smooth movement process. This is where the importance of superior caster wheels comes in.

Understanding Nylon as a material!

The name “nylons” refers to the group of plastics known as ‘polyamides’. Nylons are typified by amide groups (CONH) and encompass a range of material types (e.g. Nylon 6,6; Nylon 6,12; Nylon 4,6; Nylon 6; Nylon 12 etc.), providing an extremely broad range of available properties. Nylon is used in the production of film and fibre, but is also available as a moulding compound.

Properties

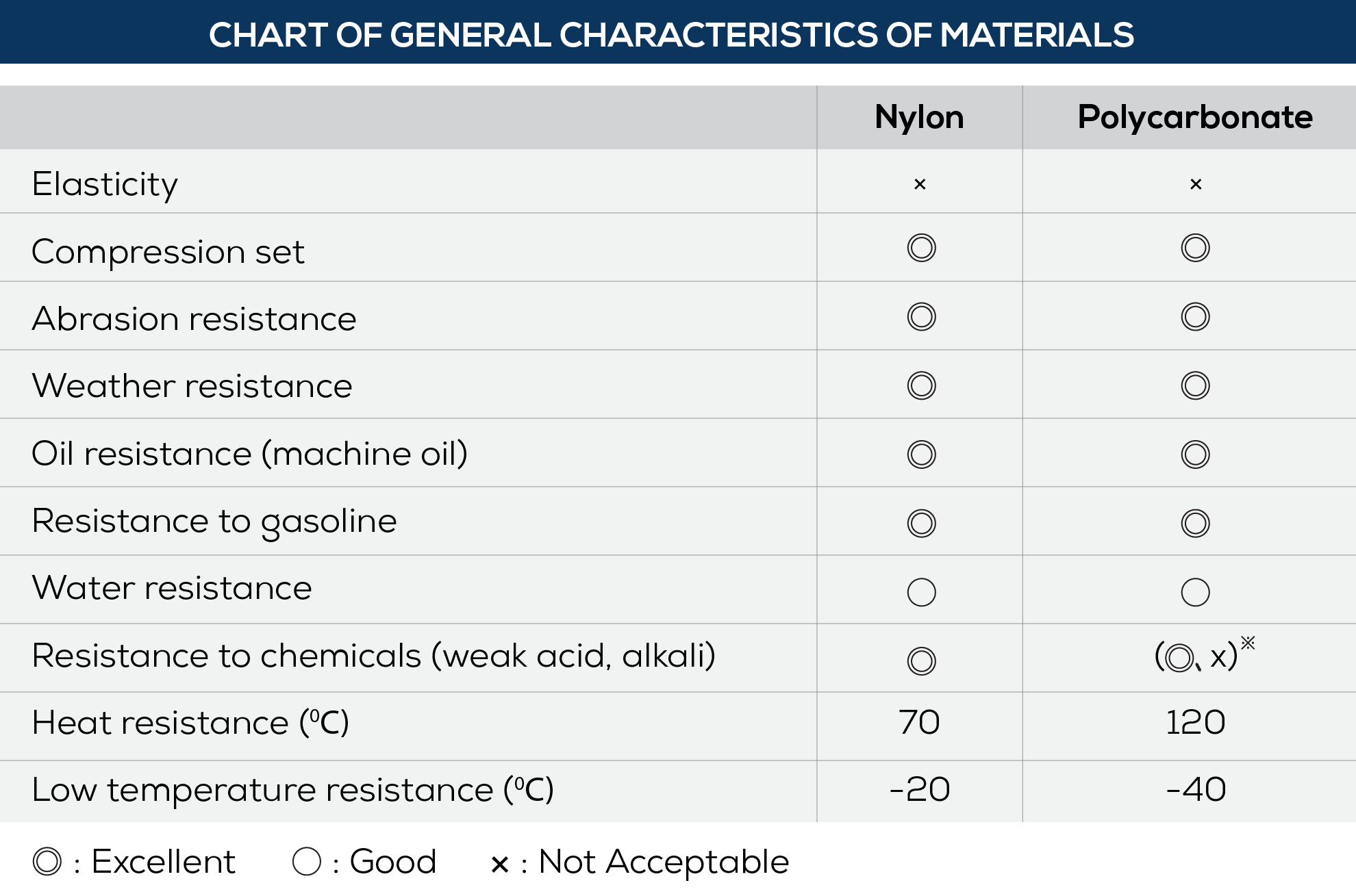

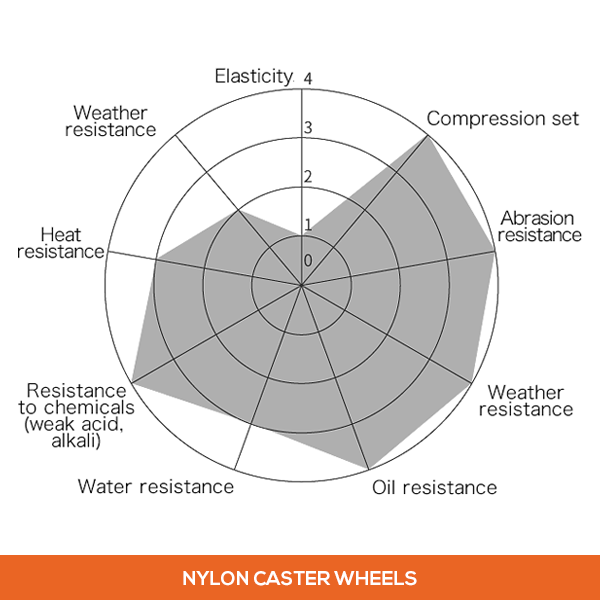

The majority of nylons tend to be semi-crystalline and are generally very tough materials with good thermal and chemical resistance. The different types give a wide range of properties with specific gravity, melting point and moisture content tending to reduce as the nylon number increases.

Nylons tend to absorb moisture from their surroundings. This absorption continues until equilibrium is reached and can have a negative effect on dimensional stability. In general, the impact resistance and flexibility of nylon tends to increase with moisture content, while the strength and stiffness below the glass transition temperature (< 50-80 oC) decrease. The extent of moisture content is dependent on temperature, crystallinity and part thickness. Preconditioning can be adopted to prevent negative effects of moisture absorption during service.

Nylons tend to provide good resistance to most chemicals, however can be attacked by strong acids, alcohol’s and alkalis.

Nylons can be used in high temperature environments. Heat stabilised systems allow sustained performance at temperatures up to 185 oC (for reinforced systems).

Physical Properties

Tensile Strength 90 – 185 N/mm²

Notched Impact Strength 5.0 – 13 Kj/m²

Thermal Coefficient of expansion 90 – 20/70 x 10-6

Max Cont Use Temp 150 – 185 oC

Density 1.13 – 1.35/1.41 g/cm3

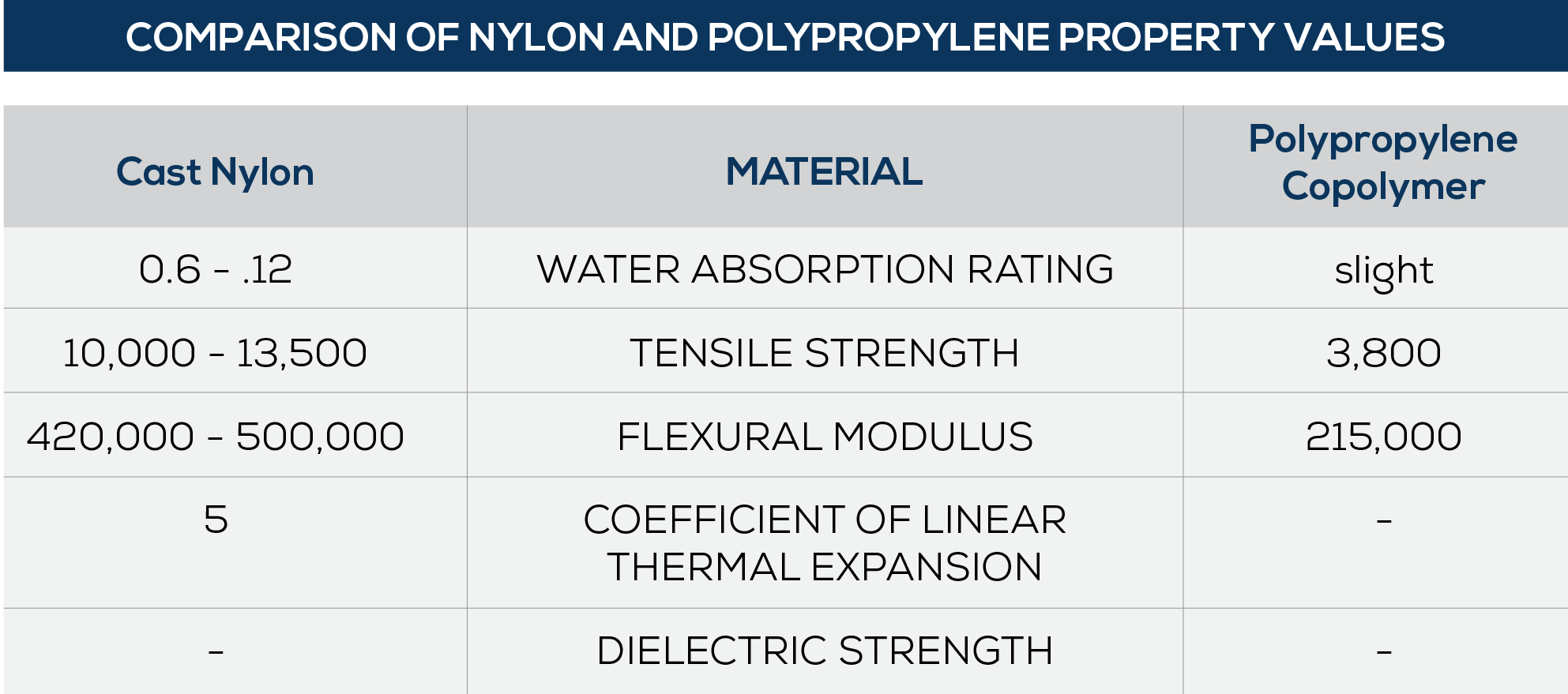

What makes Nylon Wheels preferred over other grade of polymers such as PP/PPCP ?

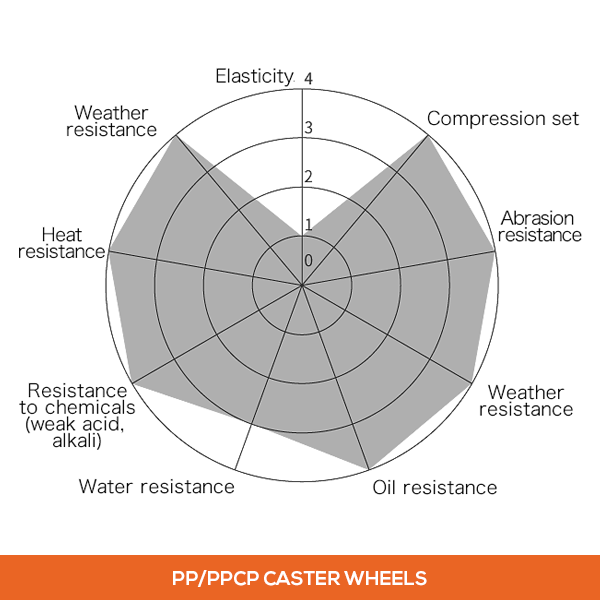

PP/PPCP Caster Wheels although are commonly used, but they often get degraded through high temperatures resulting in cracks. The material often melts when exposed to heat.

Although these wheels have less hardness and low operation sounds, they really need more force in order to carry heavy load. This not just hampers the movement, but also results in wear and tear of the wheels.

On the contrary, Nylon Caster Wheels have excellent resistance to chemicals. These are corrosion-resistant and even withstand rough handling on the uneven floors of the Spinning Mills. Light in weight, Nylon Wheels because of the material that they are made of are easy to clean and stays in good condition both in look and condition for a longer period of time.

Working closely with global clients, Jumac understands the importance of every small essential that makes sliver cans all the more effective. Superior caster wheels made of Nylon ensure precision in handling of sliver.

Thinking of ordering Sliver Cans for your mill? Explore Jumac for a great product.

Passionate about transforming the industrial sector of textile and spinning industry with innovative solutions. Director at Jumac Manufacturing, leading spinning cans and accessories manufacturer and exporter from Kolkata, India.