Over five decades of our journey, we have mastered spinning…

Sliver Can Spares & Accessories – Bringing Stability To Your Yarn Manufacturing

From sliver formation to fiber collection to yarn take-off, the role played by sliver cans is simply undeniable. But until the 1960’s, monitoring and maintenance of sliver cans were not given much importance in the plants where yarns were processed from cotton bails, neither was there was any organized market for spares and accessories used in sliver cans. With the introduction of high-tech equipment in the spinning industry, maintenance and quality of the sliver can become a priority. Apart from the quality of HDPE (high-density polyethylene) used to manufacture the sliver cans, whether the cans are in optimum running conditions or not depends totally on the spares and accessories.

The benefits of quality spares and accessories in sliver cans:

-

Energy conservation

Good quality spares and accessories contribute to cost reduction. Energy accounts for close to 25% of the total cost incurred for yarn production, out of which, up to 3.5% can be reduced by using superior quality spares and accessories for sliver cans. For instance, when the caster fittings attached to the bottom rim or plate of the sliver can match the dimensions of the spinning rotor, it eliminates the chances of slipping or tilting of the can, thereby maintaining a firm position at all times.

-

Quality matters

The quality and performance of sliver cans depend on the spare parts used for manufacturing the sliver cans as they provide strength, firmness, and support to the sliver cans. Research has proved that if the quality of the spares and accessories are compromised, it will directly affect the quality of sliver. Poor quality spares and accessories might lead to crashing of cans, leakage, improper balance management, or difficulty in handling of cans, leading to the only consequence – wastage of premium quality sliver.

-

Superior efficiency

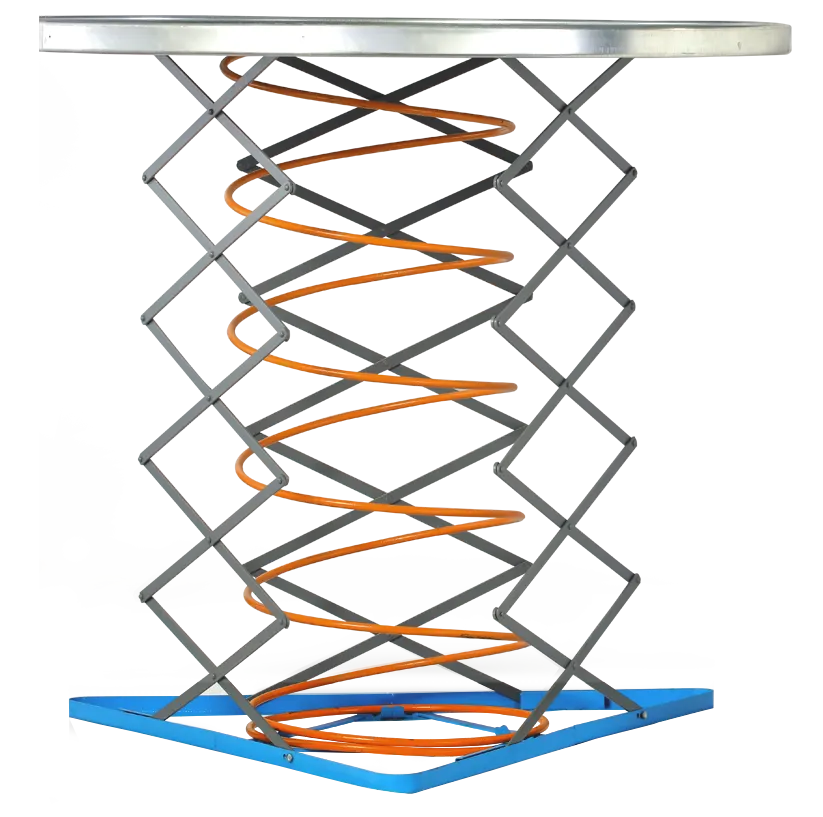

As the sliver cans are used in bulks in spinning industry, it is extremely important that they maintain a higher level of effectiveness, and balance the centrifugal force to maintain a perfectly aligned position in each and every production stage. This would be impossible without quality spares and accessories, which also make the cans flexible so that they can be moved conveniently.

-

Maximum Durability

Spares and accessories for sliver cans are always in demand as the sliver cans that are already in use are subject to wear and tear and often require spare parts to be replaced. Replacement of spares from time to time means that the sliver containers can be used for longer period of time.

-

Strong and supple

As the sliver moves towards the rotor groove due to centrifugal force during spinning, they start exerting pressure. The spares and accessories, especially the springs help the cans to bear the weight of the sliver rings thus formed. The extra reinforcement also supports seamless handling. The high-quality metal used in spares and accessories are specially treated to give heat stability to sliver cans.

Sliver cans are the most important component in the spinning factory for manufacturing of cotton yarns. 80% of the spares and accessories for spinning cans are manufactured domestically, a significant amount of being exported. Spares and accessories for spinning cans are the ones that make the yarn production smoother. At present, these are engineered according to up-to-date machinery used in spinning mills. Since productive-maintenance is the new mantra at the modern day spinning, it is better to have the spares and accessories handy for yarn production.

Passionate about transforming the industrial sector of textile and spinning industry with innovative solutions. Director at Jumac Manufacturing, leading spinning cans and accessories manufacturer and exporter from Kolkata, India.